Innovate Your Facility Today!

With Our Advanced CMMS

When dealing with high value Physical Assets, having the right CMMS solution is crucial. Aladdin is the ultimate end to end CMMS that will help you get a clear 360 view over your Physical Assets and grow your Business.

Why Aladdin?

Unlike any traditional CMMS, Aladdin is an easy to use Solution that can easily be adapted to your Business and to your staff, no matter what their background is. Whether it’s your Operations/Engineering teams or your Crews on the field, Aladdin is the Ultimate CMMS Solution.

Features of Our CMMS

Work Orders

Preventive Maintenance

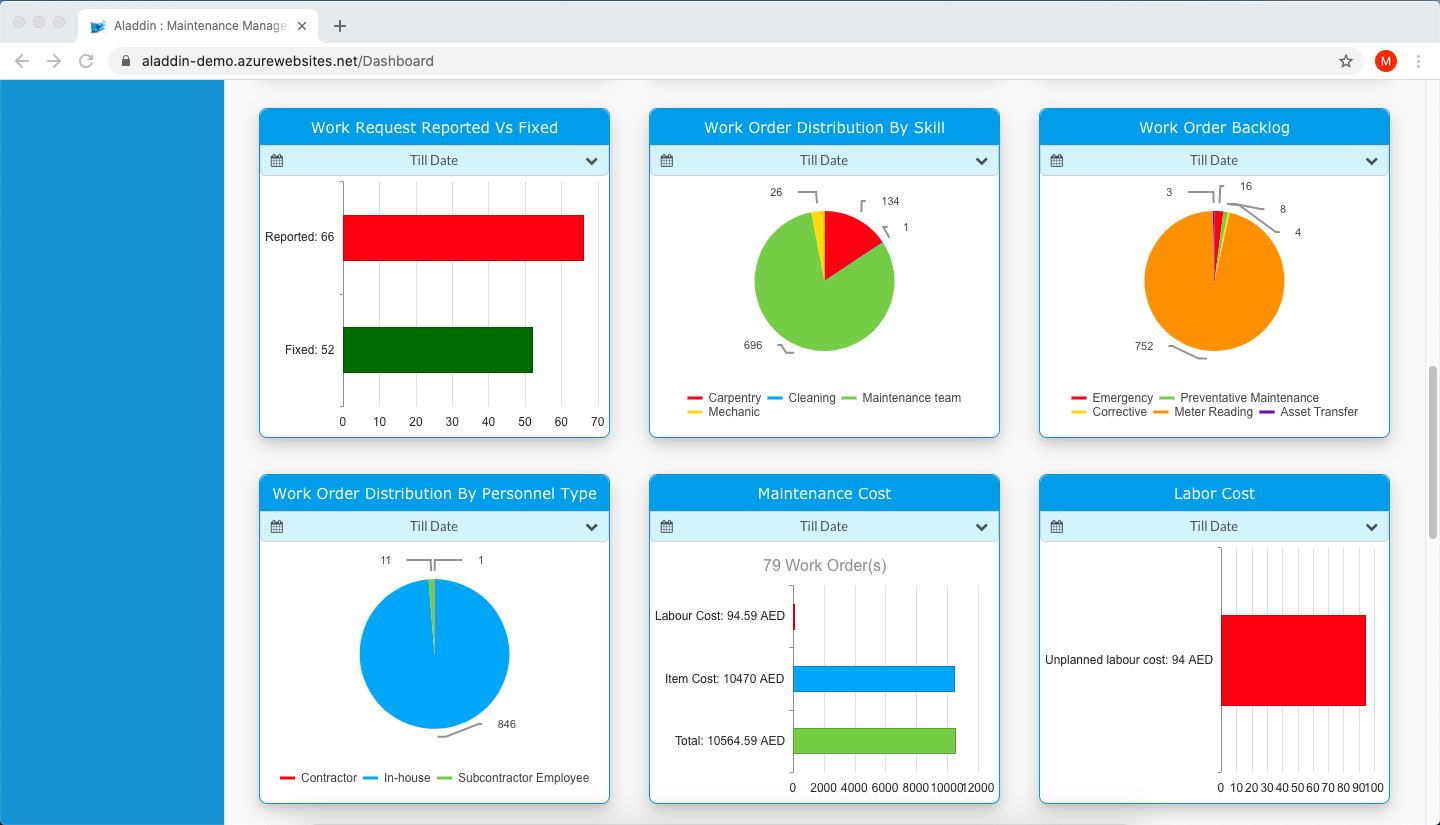

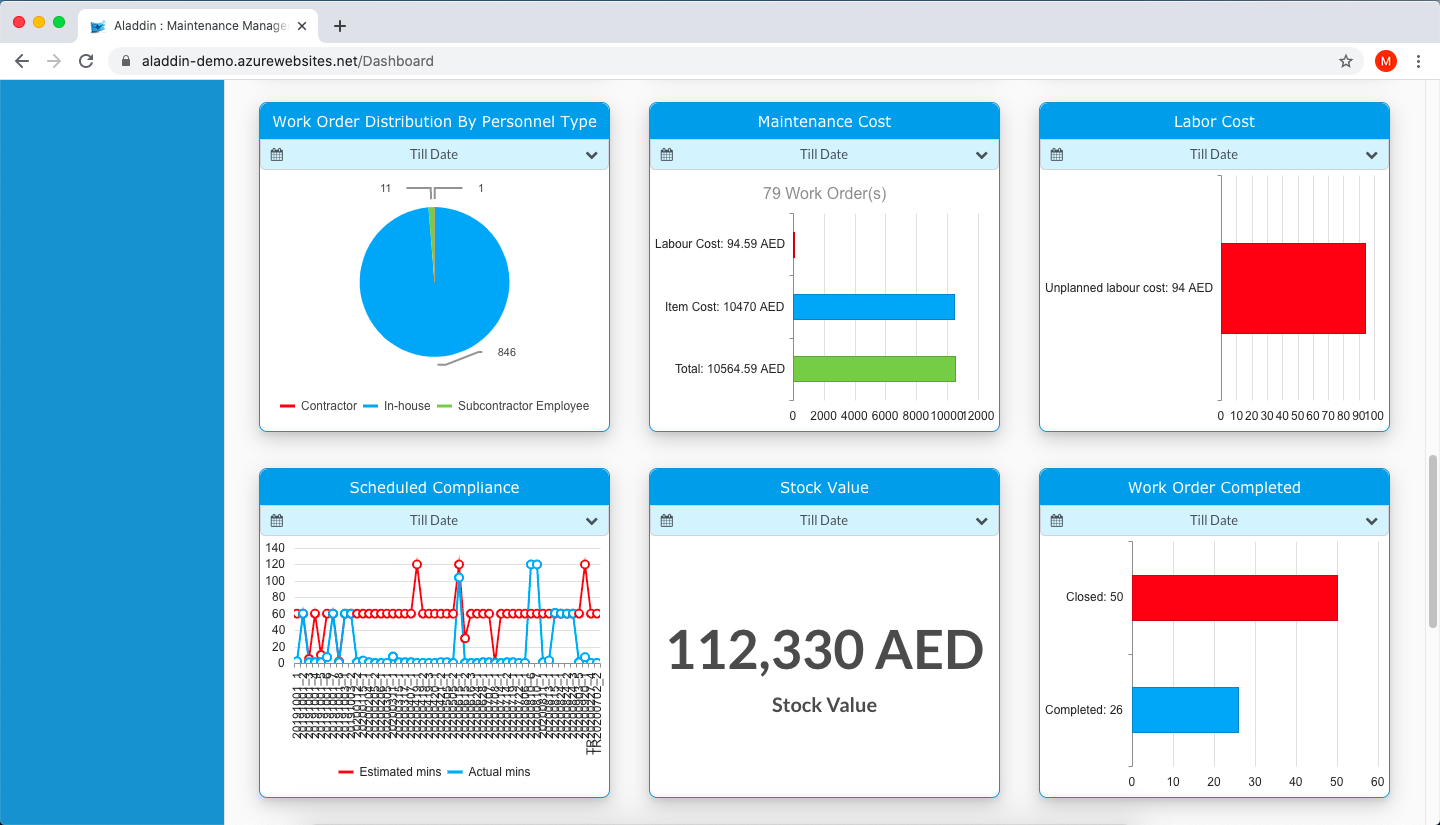

Dashboards

Aladdin’s Web and Mobile dashboards empower you with real-time, accurate data to eliminate inefficiency and make impactful decisions.

Contract Management

Aladdin easily stores and tracks your physical assets’s documentation and warranty information to enforce SLAs and hold stakeholders to account.

Reports

Asset Tagging

Through Aladdin’s Asset Tagging Solution, you can categorize and keep track of all your Physical assets in one place.

Our CMMS Delivers Proactive

Maintenance Across Industries

Healthcare

Manufacturing & Retail

Logistics & Transportation

Construction & Real Estate

Education

Hospitality & Leisure

Facilities Management

4 Easy Steps to Get Started

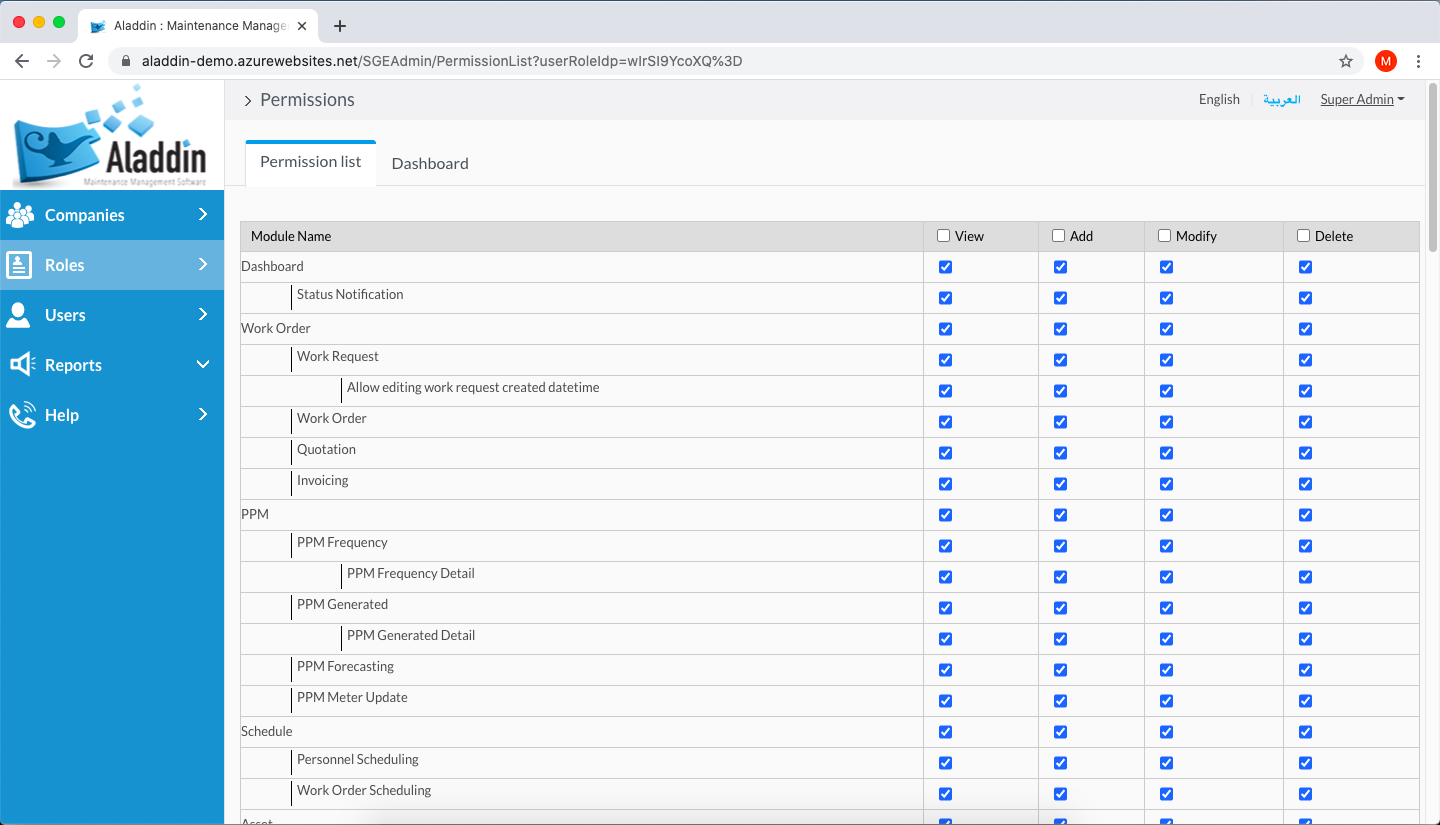

Setup Users

Define users & their roles with custom defined permission levels based on your business processes & maintenance workflows.

1

Define Physical Assets

2

Define your Physical assets using 35+ fields of customizable physical asset information or simply upload your existing asset register to unravel the industry best asset management practices.

Streamline Work Orders

3

Sit Back and Manage efficiently

Have your Physical assets tracked by tracking work orders, inventory and more. Once your setup is complete and your team is up and running with our mobile app, you’re set to take it to the next level!

4

4 Easy Steps to Get Started

1- Setup Users

Define users & their roles with custom defined permission levels based on your business processes & maintenance workflows.

2- Define Physical Assets

Define your Physical assets using 35+ fields of customizable Physical asset information or simply upload your exiting asset register if you have one to unravel the industry best asset management practices.

3- Streamline Work Orders

Automate reactive & preventive workorders swiftly and with ease via customizable and flexible processes to suit your FM and maintenance needs.

4- Sit back and Manage Efficiently

Have your physical assets tracked by tracking work orders, inventory and more.Once your setup is complete and your team is up and running with our mobile app, you’re set to take it to the next level!

Well-Equipped. Straight out of the box.

Physical Assets

We believe you know your processes best. For this reason we provide all features to everyone.

Start tracking your physical assets and saving costs the quick and easy way

What positive results could you get with an Advanced CMMS?

This calculator simulates the potential return on investment that you could realize by using CMMS software from Aladdin.

Integrate Everywhere.

Track Anywhere.

TESTIMONIALS

What People Are Saying

It all began with the need for an accurate Asset Register. Aladdin helps us define and inspect our physical assets and build an up-to-date asset register in Aladdin that comments on the real condition of our physical assets.

Whether it is a feature-rich mobile application that our crew used 24/7 or the web application that we use to plan preventive maintenance or respond to emergencies, our maintenance department’s efficiency has increased remarkably on account of Aladdin.

SGE has verified our asset registers and reconcile our books. This really helped our financial management in tracking our physical assets and making sure all asset depreciations were accurate.

Unlock the True Potential of your Business with Our CMMS

Customized Business Case | ROI Analysis | No obligation whatsoever